[Interdisciplinary] [Civil Engineering] [Chemical Engineering] [Electrical Engineering] [Mechanical Engineering]

2024 CAPSTONE PROJECTS

[Interdisciplinary] [Civil Engineering] [Chemical Engineering] [Electrical Engineering] [Mechanical Engineering]

2023 CAPSTONE PROJECTS

[Interdisciplinary] [Civil Engineering] [Chemical Engineering] [Electrical Engineering] [Mechanical Engineering]

MECHANICAL ENGINEERING CAPSTONE PROJECT ARCHIVES

[2022] [2021] [2020]

THE COOPER UNION

ALBERT NERKEN SCHOOL OF ENGINEERING

Capstone Senior Projects Showcase

2024-2025

Senior Design is a year-long experience during which students form teams and work on a major capstone design project that build on the knowledge and skills acquired within their disciplines. Students have the option to enhance this experience by working with students from other majors in a multidisciplinary team.

This experience culminates with our Interdisciplinary Capstone Showcase, an event held at the end of the spring semester during which the Cooper community is invited to hear our seniors present their work and engage in conversation about design solutions that address societal needs and grand challenges. Teams are given feedback by faculty, students, staff, alumni and invited guests from industry. The showcase is followed by an awards ceremony and celebration.

The School of Engineering capstone website provides an online record of the Capstone Projects going back to 2020.

This experience culminates with our Interdisciplinary Capstone Showcase, an event held at the end of the spring semester during which the Cooper community is invited to hear our seniors present their work and engage in conversation about design solutions that address societal needs and grand challenges. Teams are given feedback by faculty, students, staff, alumni and invited guests from industry. The showcase is followed by an awards ceremony and celebration.

The School of Engineering capstone website provides an online record of the Capstone Projects going back to 2020.

2020 CAPSTONE PROJECTS

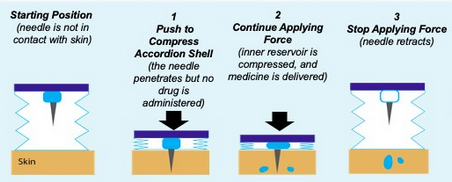

FIGHTING THE OPIOID EPIDEMIC:

A DRUG INJECTION SYSTEM

Gertrude Dabo

Naomi Javitt

According to the U.S Department of Health and Human Services (HHS), over 130 people died each day from opioid related overdoses from 2017-2018. Fortunately, there is a drug called naloxone or Narcan, which can reverse an overdose within minutes. The biggest challenge in saving an individual from an overdose is timely access to Narcan and a bystander to administer it. To combat this problem, we have created a novel device that can detect an opioid overdose, and inject the individual with the correct dose of Narcan.The device is low profile and wearable, so it will always be on hand. It consists of an accordion shell with a needle and medicine reservoir, which when compressed, can inject an individual, and then retract the needle when it is released.

LINK TO CONTENT

CARBON FIBER

COMPRESSION MOLDING

Raymond Choi

Connor Lowry

ADVISED BY PROFESSORS DAVID WOOTTON AND SVEN HAVERKAMP

The Cooper Motorsports team seeks to reduce the weight of their 2020 racecar by 20 lbs. Manufactured aluminum components like suspension uprights, the differential mount, and pedals contribute significant weight. These components have undergone constant refinement, thus it is difficult to further reduce weight without sacrificing stiffness. We propose carbon fiber bulk molding compound [CFBMC] as an alternative to aluminum. As opposed to purchasing expensive commercially made CFBMC, we developed an in-house manufacturing method. Testing rigs were made to characterize its material properties and validate our process by redesigning and manufacturing a suspension upright. Preliminary tests show that in-house CFBMC samples are 50% of the weight of aluminum, 50% of the strength, and 200% of the stiffness in tension, which achieves our minimum requirements. We expect to save at least 5 lbs overall by applying this material to aluminum componenets on the car.

SHAPE-LOCKING

CATHETER

Gregoire Caubel

John Nguyen

ADVISED BY PROFESSOR ERIC LIMA,

DR. ANTHONY COSTA,

AND ALEXIS BRUHAT

CATHETER

John Nguyen

80% of strokes every year are ischemic in nature, meaning a physical clot blocks blood flow to a certain region of the brain. Physicians only have 4.5 hours to intervene after a stroke event, and commonly use neurovascular support catheters to physically remove the blockage. These catheters need to be flexible enough to maneuver around complex vasculature, but rigid enough to hold their position during an operation. Instability of these support catheters caused by buckling can lead to longer surgical intervention times and greater risk for the patient. The aim of this project is to develop a computer simulation to better understand the dynamics of a catheter within the aortic arch and to use the simulation to determine the feasibility of a variable stiffness mechanism for improving the operational stability of support catheters.

LINK TO CONTENT

LINK TO CONTENT

REFLECTIVE SOLAR

CONCENTRATORS

FOR CUBESATS

William Morris

Brian Lee Aqib Sadique

ADVISED BY PROFESSOR DAVID WOOTTON

CubeSats are small, modular satellites that are popular for commercial, scientific, and educational use due to their low cost and ease of manufacturing compared to traditional satellites. However, their power systems are still costly and limited in power generation capacity due to their small surface area. A power system utilizing a deployable reflective solar concentrator would mitigate these problems; a large reflector would increase the amount of sunlight collected, thereby increasing the power generation. Additionally, the concentrator would only require solar cells along the focus of each reflector, which would decrease costs compared to a traditional solar array of comparable size.

LINK TO CONTENT